Complete Crankpin Recovery, Straightening & Heat Treatment

The Metalock Engineering Group provides cost-effective crankshaft recovery services involving crankshaft straightening, heat treatment and re-machining. We can repair most types of large diesel engines, at sea or on land, anywhere in the world.

Our Repair Process

- Straighten the crankshaft

- Anneal the crankpin journal diameter to

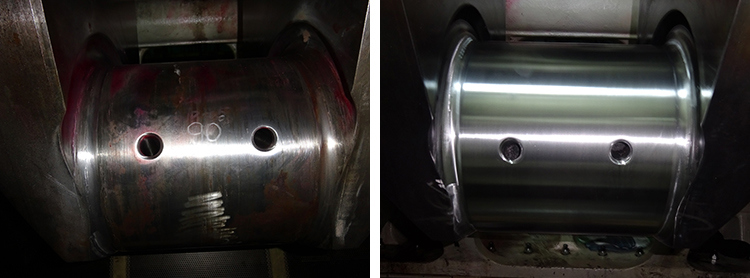

reduce hardness - Re-machine and polish the journal diameter

- MPI inspection

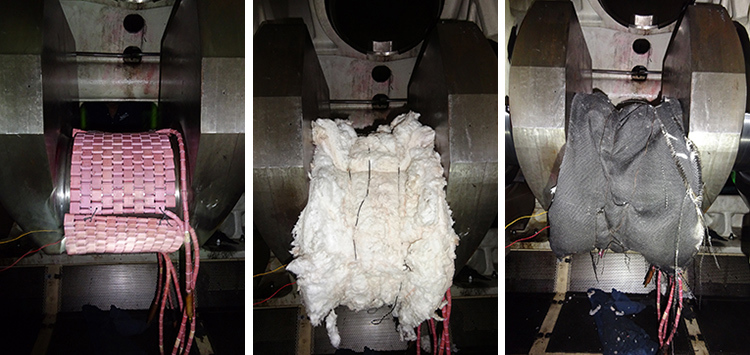

Controlled Heat Treatment Process

The purpose of local heat treatment on the journal diameter is to reduce the overall hardness to an acceptable level to allow corrective re machining.

The heat treatment is performed by a Cooper Heat thermal heat unit, which is programmed to carry out this method in a controlled manner to a temperature which is below the actual tempering temperature of the shaft during manufacture. This method causes no influence on the basic mechanical properties on the material. As a result the martensitic microstructure of the hardened areas will then be tempered and form martensitic, which is more ductile while at the same time reducing the residual stress in the journal diameter.

Heating Rates: 50deg C/hour to 600deg C holding at this for 4 to 6 hours (depending on the hardness).

Cooling Rates 50deg C/hour to 200deg C at which time the thermal blankets can be removed to allow the journal to cool to normal temperature.

We use a 400V 50KVA unit along with two thermal programme units. Triple splitter cables will be attached to the ceramic thermal blankets which are wrapped around the damaged journal diameter. Thermocouple wires are placed under the blankets on the actual journal in strategic positions to best control the temperature directly. When this is complete, the journal will be wrapped with insulation.

The heat treatment is carried out non-stop from start to finish and has to be applied to the whole journal to minimise the possibility of deformation to the crankshaft or the journal.

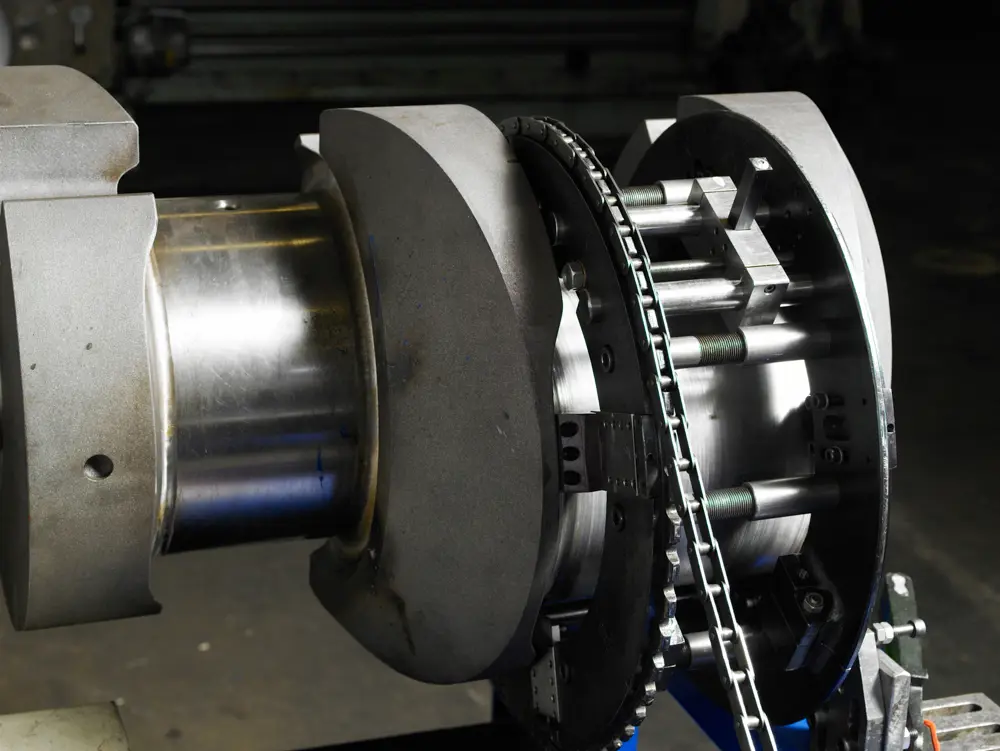

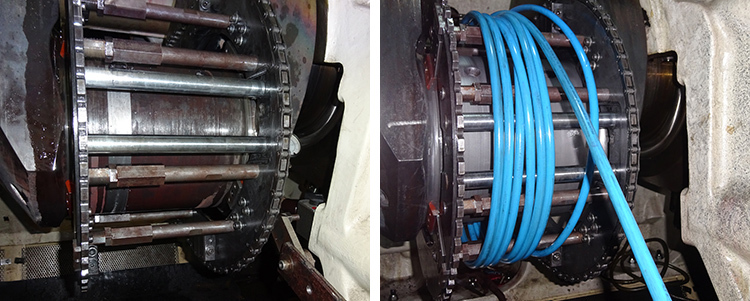

Crankpin Journal Machining

- Machining the journal

- Machining the undercut either side of the journal diameter

- Machining the fillet radi between the undercut and the web

- Polishing, Superfinishing and and dressing oil holes and radi

The Benefits of Trusting Metalock

From marine propulsion to industrial power generation, our crankshaft reconditioning and crankpin machining service gives you valuable benefits:

- 24/7 global response – just call us for support.

- A proven, solution-focused approach.

- Save money and time when it really counts.

- Avoid premature capital expenditure for engine replacement.

- Extend engine service life with damaged crankpin repair.

- Providing workshop quality service on site, in dry dock or at sea.

- One reliable source for these and many other specialist engineering services.

Submit an Enquiry

Find out how our experience with crankpin recovery can help save you time and money.