The Metalock Engineering group has served the global pressing and forging industries for decades and have a wealth of experience in all types of press repairs.

We work on all types of presses owned by many of the major manufacturers including Ball Corp, Crown, Carnaud, Minster, General Motors, Nissan, Jaguar Land Rover, Sheffield Forgemasters, Arconic and Doncasters. OEMs: Clearing Schuler, Hitachi Zosen, Aida Bliss, Danley, Wilkins & Mitchell, Massey, Fagor and Cowlishaw & Walker.

UNIQUE FORGING PRESS LEG REPAIR

Typical Press Machining Repairs

- Lower Bolster re-machining or re-grinding

- Upper Platen re-machining or re-grinding

- T Slot cutting (new or old)

- Machining vertical slide ways

- Bearing housing cylinder boring

- Gearbox in-line boring

- Crankshaft machining

- Boring Hinges on Jaws of Forging Press Manipulator

Boring Hinges on Jaws of Forging Press Manipulator

Maximum Machinery Availability

Metalock has grinding machines specifically designed for the re-grinding of press lower bolster faces and if required, we can also invert the grinding machine and re-grind the upper platen face if required. In addition, we have milling equipment that can cut new or refurbish old T slots.

Re-machining moulding press vertical platen

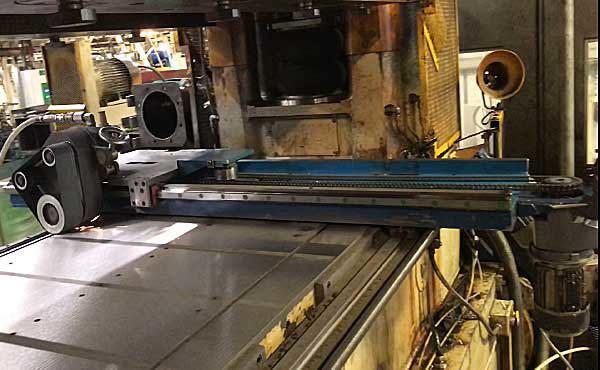

Re-grinding a press bed using a bespoke purpose built grinding machine.

Upper and Lower surfaces finished flat and parallel to one another using our custom built press bed grinding machine..

Finished machining

Do you remember the ‘bad old days’ of manual resurfacing?

How long it took, the lost production as your presses stood idle, and the challenge of achieving tight working tolerances using traditional methods?

Nowadays, when quality control indicates that presses are worn due to extensive production, it’s easy to schedule a preventative visit from our team before the condition of your press bed goes out of spec.

That’s why our in-situ machining division specialises quick and accurate press bed regrinding on your press-beds before their condition becomes critical and production suffers.

Our horizontal traversing grinding table can complete the work cost-effectively, bringing your press bed back into specification.

Huge Time Savings; Incredible Accuracy

We can reinstate one surface on a press bed, such as an ECH-125, in around three shifts, depending on the amount of wear present. That’s quick when compared to the time the traditional manual method took to resurface the bed.

We can restore the flatness and parallelism between the lower bolster to within 0.05mm.

We support a diverse range of pressings companies making products from beverage cans to automotive components.

We can also achieve superb results when machining vertical surface on an injection moulding press using our on-site CNC-controlled milling equipment.

Cold Metalock repairs on cracked press die for the automotive industry

Submit an Enquiry

How can we save you time and money, and build your reputation for getting plant and equipment working again as fast as possible?

We support a diverse range of pressings companies making products from beverage cans to automotive components.