Power Plant and Hydro Repairs

With the global power generation infrastructure having such strategic importance, even small breakdowns can have massive implications. For decades now, Metalock Engineering has been helping operators and OEMs keep the lights on.

Metalock in Action

Location:

Askim, Norway

Mission:

Solbergfoss Hydropower, Norway

Challenge:

Turbines are leaning approx 2mm. Leakage has occurred, operating efficiency down to 75%.

Solution:

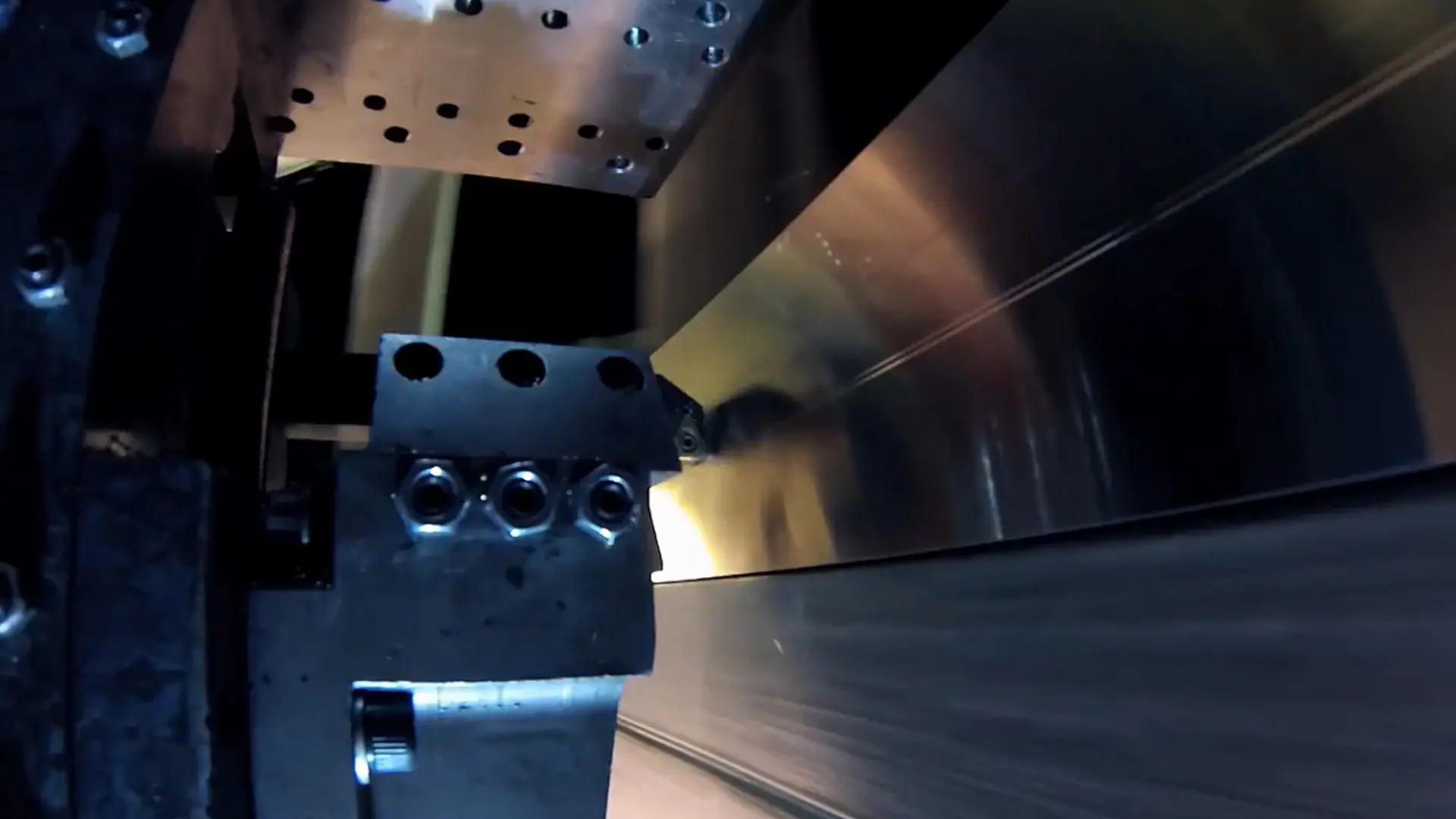

Insitu machining of a split ring to correct the error - with a tolerance of 0.0 - 0.1mm.

A 4 tonne Metalock designed boring/facing machine was taken down to the turbine chamber. 17 meters under water level.

The machine was set up with 0.02mm perfection using laser control.

Result:

The work was carried out on 21 days. The turbine can operate for 50 more years, The operating efficiency is now 90%.