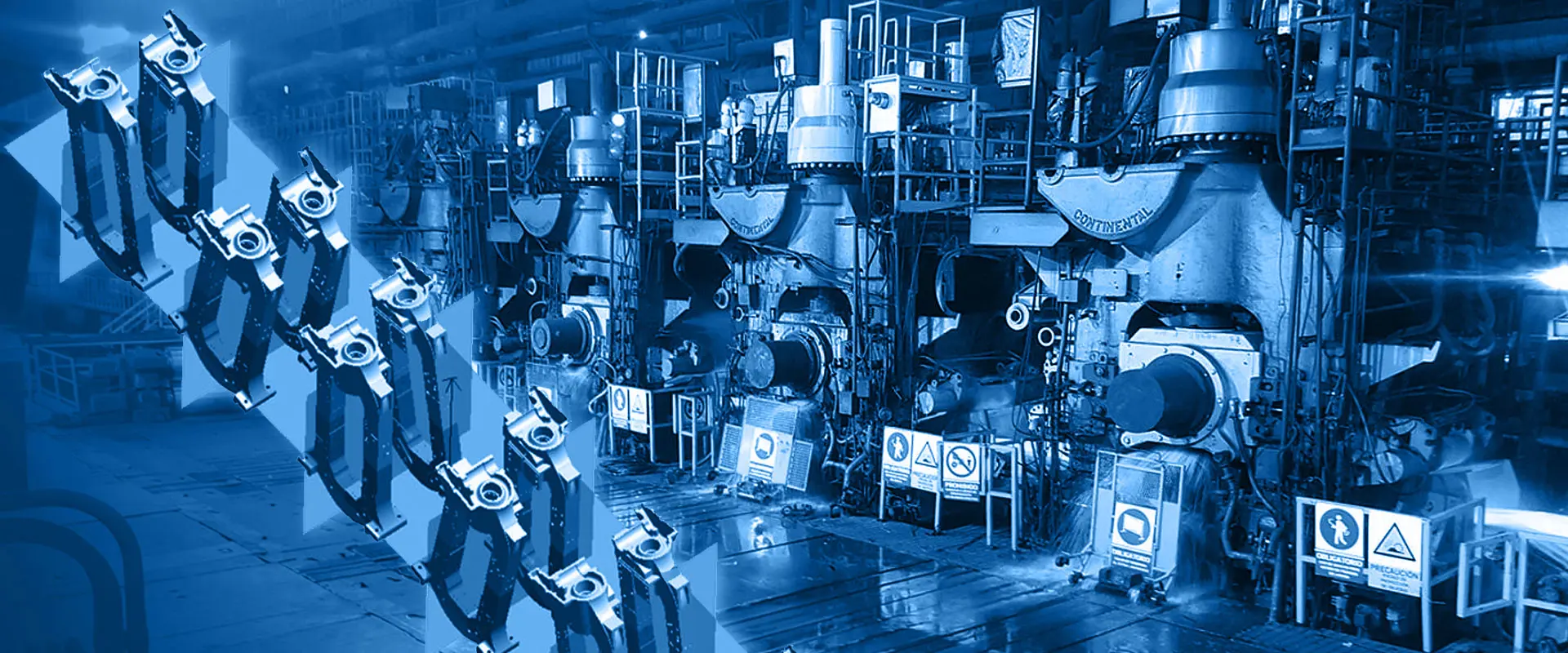

Laser tracking provides the ability to take and record accurate measurements in all types of environments.

To create and leave a permanent metrology network reference systems that will allow the laser tracker to position its self in the same place, time after time. Creating permanent reference points to work from, months or even years into the future.

This enables the mill engineers to collect measurement data at regular intervals that will monitor the level of wear, movement or deterioration of all types of plant and equipment.

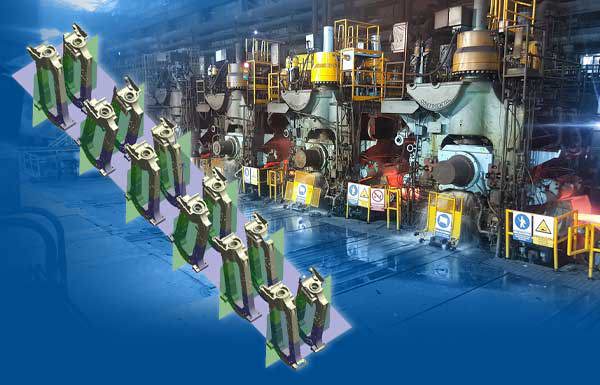

Metrology survey data before corrective CNC machining operations

An in depth survey will establish the position and condition of the millstand RCS to DS and the relationship between all 6 stands.

The results of these surveys will determine the extent of the corrective activities and enable our machining team to provide more accurates cost and duration times.

Submit an Enquiry

Using the latest laser surveying equipment Metalock are able to measure even the most obscure components and structures and provide accurate images and data that can assist the customer in making educated decisions prior to any capital investment.

Our metrology engineers arrive on-site, produce a detailed survey review and analyse full steel and aluminium mills to pick up on long-lost datum’s of even the most dated mills.