Regular Maintenance and Shut Down

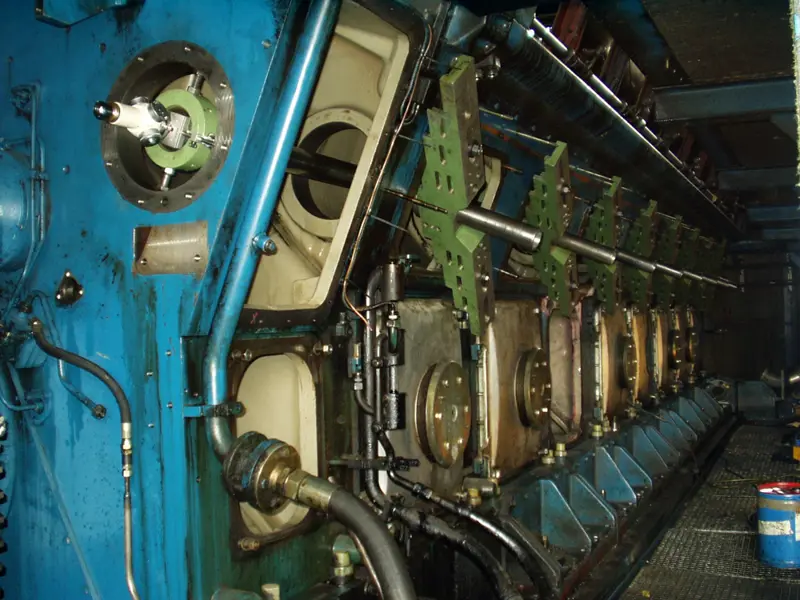

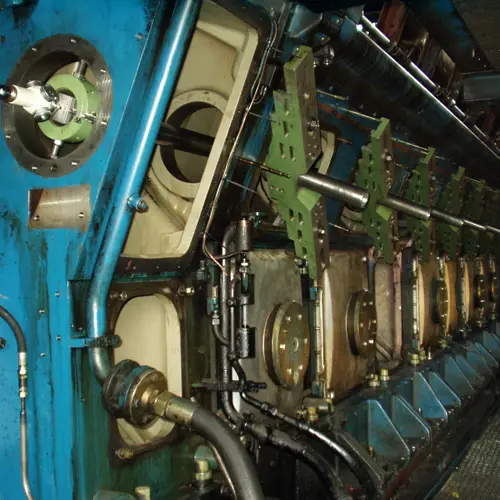

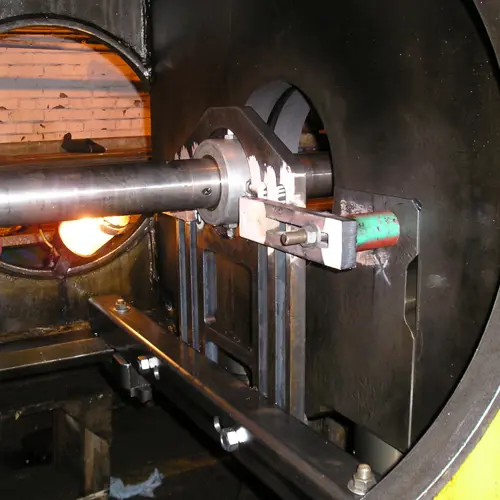

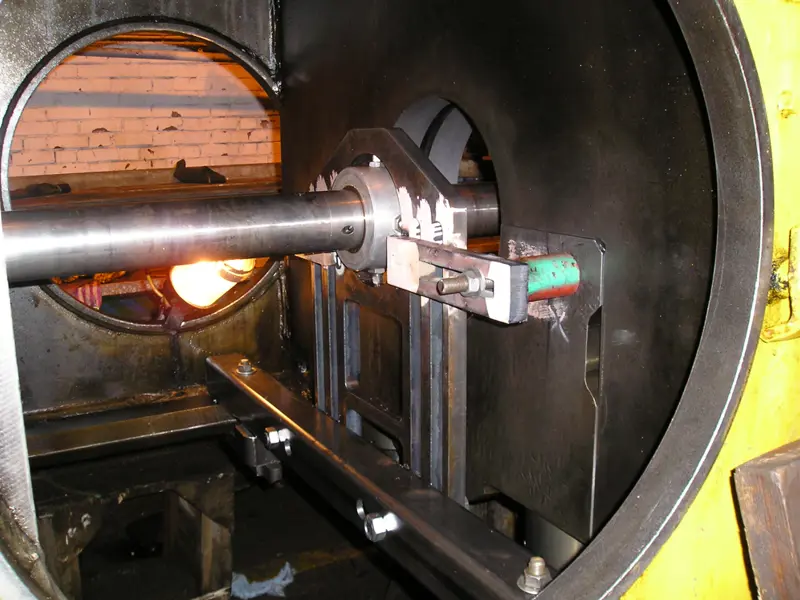

Line boring of steel mill gearboxes, mill stand screw-down bores and crop shears are some of the activities we carry out for the international steel production industry. We realise the enormous forces, pressures and temperatures, which these machines are subjected to and we complete upgrade projects all around the world every year for steel producers and OEMs.

Assisting companies in their regular maintenance and shut down work as well as major projects form part of our daily activities. We welcome partnerships and liaise with our customers to plan, co-ordinate and execute projects on time and on budget.