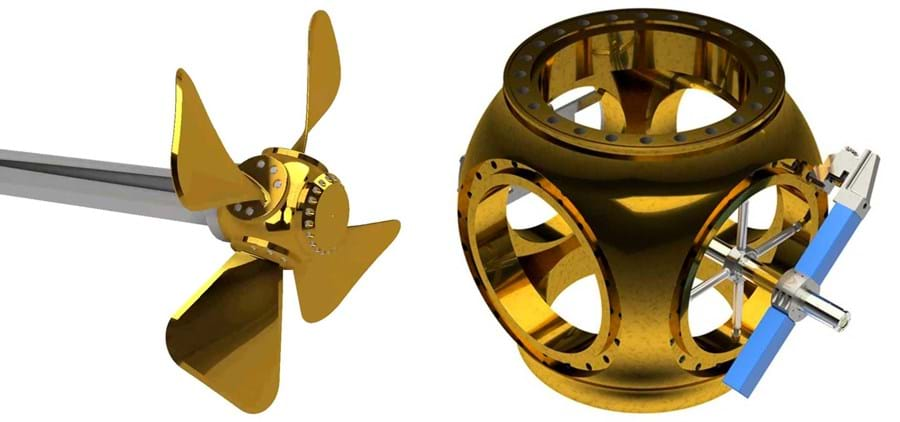

As an experienced marine shipping company operator, you know the effect of damaged propellers and hubs on vessel performance. At worst, there’s the cost and inconvenience of premature propeller loss and emergency repairs while your vessel stands idle with a worn shaft or propeller hub.

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers