With over 50 years experience in the marine & offshore industry,

you can rely on Metalock with your Diesel Engine repair or overhaul.

We are on call 24 hours daily 7 days a week. With technicians strategically located throughout our global service centres, and available at short notice to travel anywhere in the world, we are organised to provide a rapid response service to deal with emergency breakdowns 365 days of the year.

All personnel are familiar with onshore and offshore working environments and demands placed upon them to achieve program and get the job done in a safe and efficient manner.

Caterpillar 3606 Engine Block Repair

Caterpillar 3606 Engine Block Repair

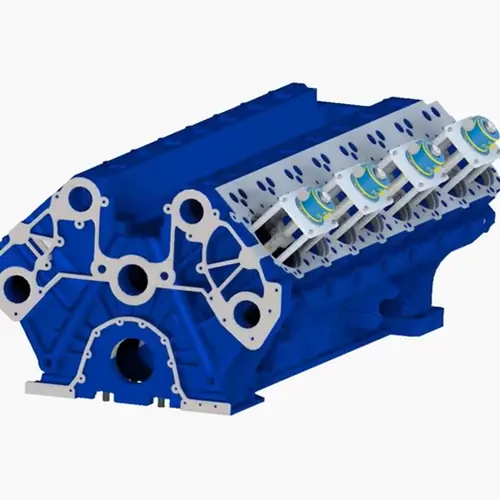

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

Wartsila 18V

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

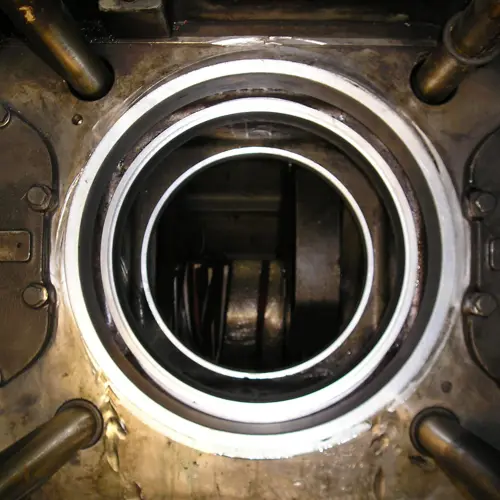

Diesel Engine -Block - Upper and Lower Liner Landings

Diesel Engine -Block - Upper and Lower Liner Landings

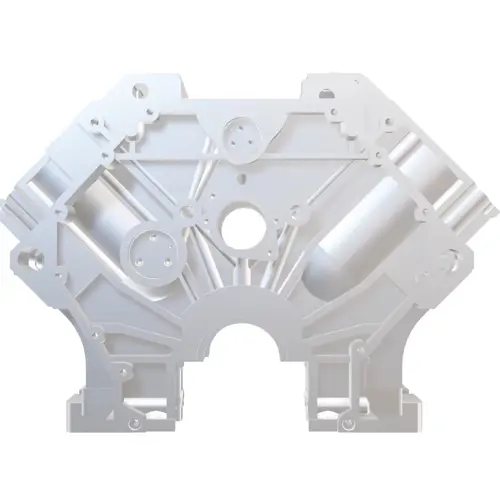

Diesel Engine – Main Bearing Pocket Transplant - Metal stitching

Diesel Engine – Main Bearing Pocket Transplant - Metal stitching

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers