What is a Hydraulic Press?

So, what exactly is a hydraulic press? This is a machine that generates a compressive force with the use of a hydraulic cylinder. A hydraulic press can exert a tremendous amount of force without much input power due to Pascal’s Principle, which states that pressure applied to confined fluids transmits equally in all directions.

The hydraulic press works by pumping hydraulic fluid into the cylinder. This pushes the piston down and creates a compressive force on the platen. The force can be precisely controlled by adjusting the amount of fluid and the pressure.

Metalock have been supporting OEMs and press operators all around the world for over 70 years. We can offer many engineering services that support maintenance and repair activities. We have completed hundreds of complex repairs on Forging Presses, Injection Molding Presses, Extrusion Presses, Stamping Presses, Canning Presses across the world.

Laser Tracking surveys record accurate laser measurements to establish the working position of the press. This highlights any areas that are working or out of alignment.

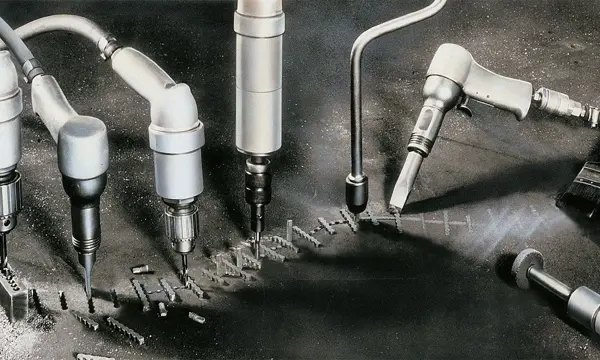

On Site machining – portable milling, boring and grinding in situ to re-grind bolsters, platens and vertical slideways. Rebore crossheads or re-machine vertical press legs.

Metalock Cold Casting repairs for any cracked or broken cast iron press frames, tools or dies.

Welding repairs

3D Laser Scanning to create engineering drawings of damaged parts to enable you to manufacture new parts which saves expensive replacement.

Davy Ashmore 1500T Press

Davy Ashmore 1500T Press

Davy Ashmore 1500T Press

Davy Ashmore 1500T Press Minster ECH-125 CP Press bed regrind

Minster ECH-125 CP Press bed regrind