This includes casing split line joint face machining services for vertical and horizontal casings. Keep reading to learn all about this repair service and why you should choose us for your machining needs.

What Are Split Line Joint Faces?

Split line joint faces are the interfaces where two halves of a casing meet and are joined together. The two halves, usually the upper and lower or left and right, join to enclose the internal components. The joints are used to provide precise alignment and ensure proper sealing, which helps to protect internal components and maintain the overall integrity of the equipment.

Split line joints are used in many different types of equipment, including turbine casings, compressor casings, pump casings, and gearboxes. For all of this equipment, it is essential that joint faces are smooth and properly aligned for reliable and efficient performance.

Industries Where Split Line Joint Face Machining is Key

There are many industries where split line joint face machining is important for equipment performance. These include:

Manufacturing: There are many types of rotating machinery that depend on precisely aligned split line joints for optimum performance, including gearboxes and presses.

Marine & Offshore: Split line joints in marine engines, turbines, and compressors are used, and precise machining is key for making sure that components are able to withstand extreme marine conditions and heavy-duty operations.

Oil & Gas: In the oil and gas sector, compressors and pumps are used in refineries and depend on strong split line joints to withstand extreme pressures and temperatures. Joint machining is key for proper sealing and alignment.

Petrochemical & Chemical Processing: Pumps and compressors in chemical plants have extreme conditions, so split line joint face maintenance is key for preventing leaks and maintaining the structural integrity of the equipment.

Common Problems With Split Line Joint Faces

There are a few issues that can arise with split-line joint faces. This is because they are often used in extreme conditions and must withstand significant stress as well as continuous operation. This means that a number of issues can develop over time:

Wear & Distortion: The joint faces can become worn or distorted due to operational stress, thermal cycling, and mechanical loads.

Misalignment: Misalignment is another common issue that occurs due to improper installation, operational shifts, and wear. Misalignment is problematic because it can lead to uneven loading and reduced efficiency.

Corrosion: Corrosion can impact the structural integrity of the joint face and is a result of exposure to extreme environments, such as chemicals, moisture, and heat.

Surface Damage: Surface damage, including cracks and uneven surfaces, can occur due to mechanical impacts or long-term usage, which can compromise the functionality of the joint.

Metalock’s Split Line Joint Face Machining Services

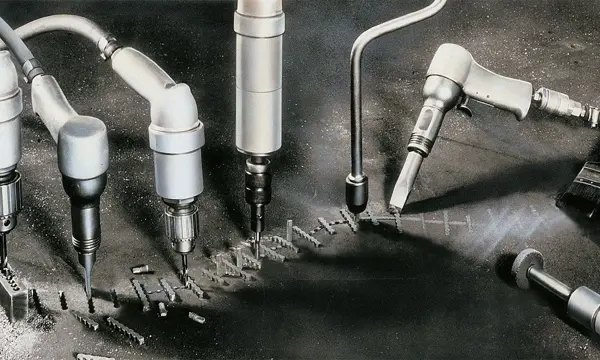

Here at Metalock Engineer, we have expertise in machining services that can restore your split line joint faces on both vertical and horizontal casings. We use precise and advanced techniques that allow for precise restoration, which can improve the performance of your critical equipment and extend its lifespan - this can help you make significant long-term savings.

On-site Machining

One of the main reasons to choose Metalock Engineering for your split line joint face machining needs is the fact that all machining is carried out on-site. This means that you do not need to dismantle your equipment and send it away - we can come to you to keep disruption and downtime to a minimum. We can perform surface restoration, alignment correction, and crack repairs using our patented metal stitching technique. This means that if you are experiencing issues with your split-line joint faces, you can feel confident that we have a solution.

24/7 Support

Another reason why you should choose Metalock for your split line joint face machining requirements is the fact that we provide 24/7 support. You can contact us round the clock and 365 days a year - even on Christmas Day! We are equipped to respond to your needs quickly so that you can keep downtime to a minimum.

Global Reach

MetaLock Engineering has a strong global presence serving over 100 countries all around the world. We have our skilled technicians strategically located, which allows us to send someone close to you so that the machining can be carried out as quickly as possible.

Cost Effective

You will also find our split-line joint face machining services to be cost-effective. This is because we can keep downtime to a minimum by carrying out the service in situ but also due to the fact that we can prolong the life of your industrial equipment. In addition to this, you will find that our machining services are more economical than replacing the entire casing.

Safety & Quality

Finally, safety and quality are at the core of our operations. All of our technicians are highly trained, so you can rest assured knowing that they will be able to work safely and exceed industry standards. We are global leaders in specialist engineering repairs, so you know you are in safe hands with Metalock Engineering.

Get In Touch Today For Our Split Line Joint Face Machining

If your split line joint faces are worn, damaged, or misaligned, it is vital that you get them restored. We have expertise in this area with our split-line joint face machining services. We can restore your casing to its original specification and carry out machining in situ, which prevents disruption to your operation and helps keep the costs of downtime to a minimum.