Wherever you are in the world the Metalock Engineering Group offer a wealth of on-site machining skills and experience to salvage diesel engine crankshaft main-bearing and big end journal diameters on large and small engines.

Precision on-site crankpin machining saved P&O time and money, and avoided the hassle of costly machinery removal, when the crankpin on one of MS Pride of Bruges’ two Wärtsilä-Sulzer 9ZAL40 engines required repair. Successful completion of the work demonstrated yet again how we tackle the toughest marine and land-based machining challenges anywhere in the world and around the clock.

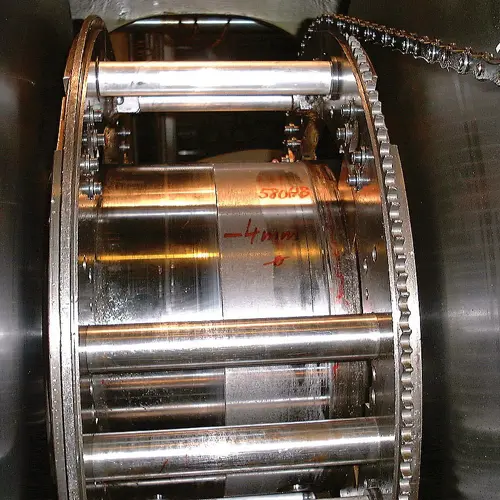

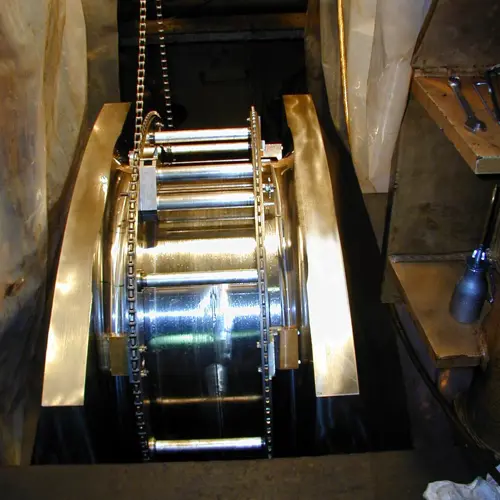

Main Bearing Pocket Machined Whilst Crankshaft Remains In Situ

Main Bearing Pocket Machined Whilst Crankshaft Remains In Situ

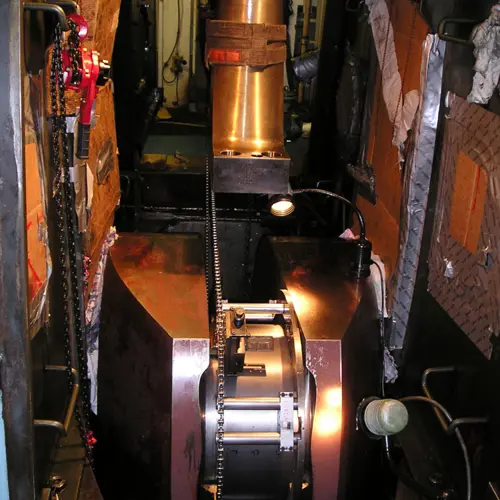

Another View To Crankpin Machining Crop

Another View To Crankpin Machining Crop

-

-

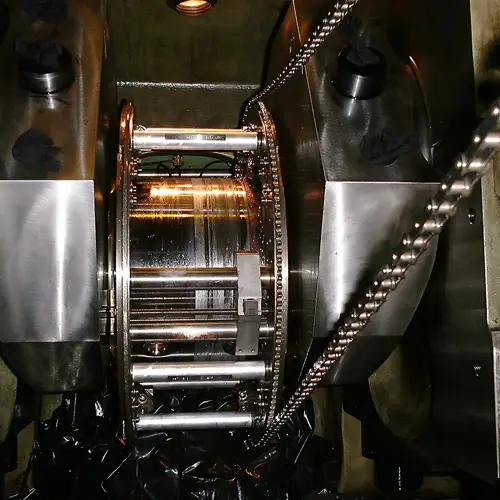

Main Crank Pin Machining

Main Crank Pin Machining

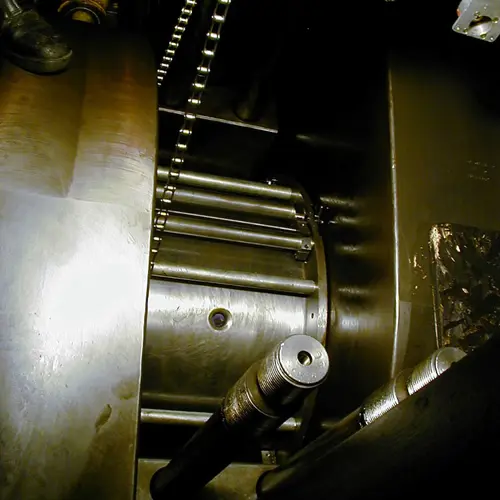

Page Machining Crankpin Diameter

Page Machining Crankpin Diameter

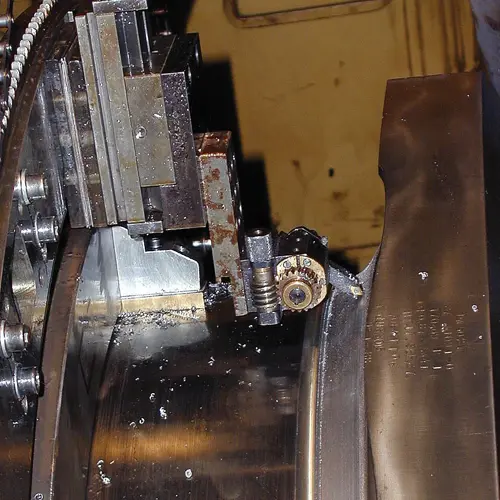

Page Machining Fillet Radius

Page Machining Fillet Radius

Crankpin Machining

Crankpin Machining

Unscrew Crankpin

Unscrew Crankpin

Crankpin And Main Bearing Journal Diameter Machining

Crankpin And Main Bearing Journal Diameter Machining

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers