The world of engineering is changing to incorporate new technologies that provide essential data as to the operating position of plant and equipment and its’s relative position to associated plant and machinery. When equipment is aligned correctly everything operates with increased efficiency.

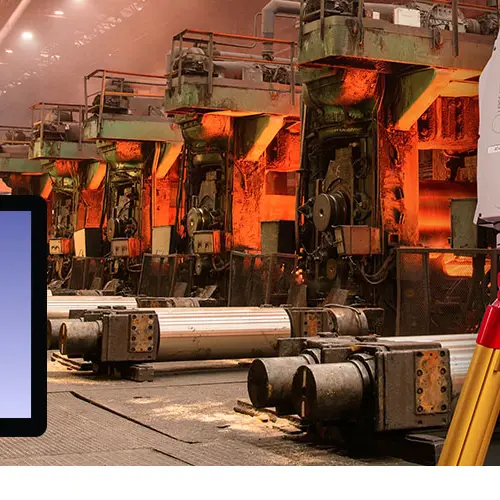

Metalock metrology engineers arrive on-site, produce a detailed survey review and analyse full steel and aluminium mills to pick up on long-lost datum’s of even the most dated mills. Even without physical references in the way of landmarks, using laser technology our survey department has been able to ascertain the pass line of the material and centre line of the steel mill and individual stands by analysing the surveyed data. Read more about Metrology in steel production.

Laser alignment and surveying have become an invaluable asset relating to onsite machining.

Alignment health check for production of rolled product.

Alignment health check for production of rolled product.

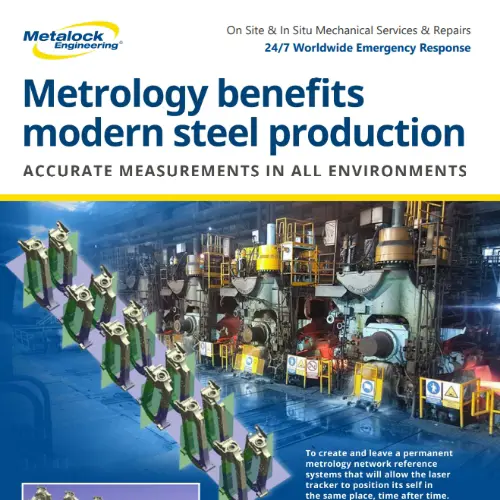

Permanent reference networks (mill datum references)

Permanent reference networks (mill datum references)

-

-

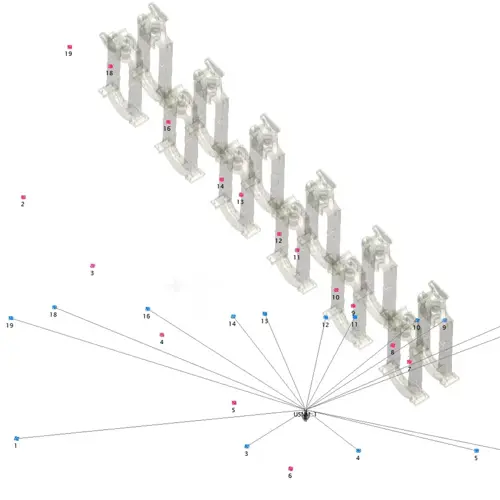

3D Representation

3D Representation

Metrology In Car Manufacturing

Metrology In Car Manufacturing

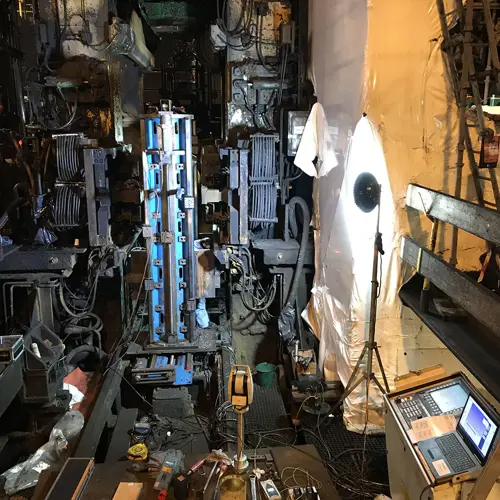

Metrology Department In Action

Metrology Department In Action

Machine

Machine

Machine In Case

Machine In Case

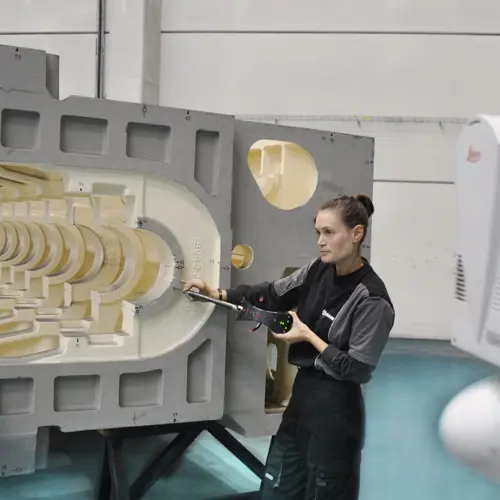

Metrology In The Aerospace Industry

Metrology In The Aerospace Industry

Marine Offshore Industry

Marine Offshore Industry

-

-

-

-

-

-

Metrology benefits modern steel production

Metrology benefits modern steel production

Get in contact

How can we help you? We offer a 24/7 worldwide emergency response. Please select from the options below to contact us.

Submit an Enquiry Office Locations Quick Contacts Careers